AnoPolish is Anoplate’s proprietary electropolishing process for a variety of stainless steels, Invar, and Kovar.

AnoPolish is Anoplate’s proprietary electropolishing process for a variety of stainless steels, Invar, and Kovar.

Electropolishing, as its name implies, refers to chemical polishing of various metals in an acid solution using electricity. The process works by electrochemically removing high spots on the part, but on a micro-level. AnoPolish is typical results in a two-fold decrease in the surface finish of the part.

AnoPolish used on medically-invasive surgical instruments and bone plates to improve corrosion performance and sterilization ability.

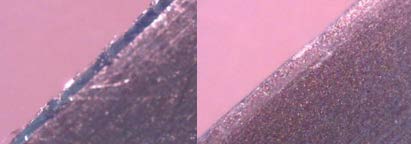

AnoPolish can micro-deburr an edge (left), leaving the edge nice and smooth (right). By itself, AnoPolish is not a deburring process.

SPECIFICATIONS

❖ AMS 2700

❖ ASTM A 967

❖ ASTM A 380

❖ ASTM F 1089

KEY ADVANTAGES

❖ Improves lubricity through smoother surface finish

❖ Improves corrosion resistance

❖ Removes micro-burrs

❖ Offers excellent reflectance and sheen

❖ Removes impurities inherent in the machining/ bending/ welding process

❖ Relieves stresses in the part imparted by cold-working of machining

❖ Can be used to right-size parts that are over-tolerance

❖ Improves the sterilization-ability for invasive surgical instruments

APPLICATIONS

❖ Medical Implants & devices

❖ Food processing & handling eq.

❖ Pharmaceutical/ laboratory eq.

❖ Gears & spines Anoplate Corporation • 459 Pulaski Street • Syracuse, NY

--

anodizing, metal finishing, surface treatment, anopolish, news, events, industry updates, metal coatings, corrosion protection, surface enhancement, metal finishing solutions, industrial coatings, surface engineering, metal plating, anoplate.