A family of chemically deposited electroless nickel (EN) coatings.

Technical Data Sheet - ENhanced Nickel

By varying the percentage of phosphorus, Anoplate provides a broad family of electroless nickel finishes that are formulated to meet precise engineering needs.

Strict control of bath parameters allows Anoplate to offer uniquely developed EN coatings with specific physical and metallurgical properties.

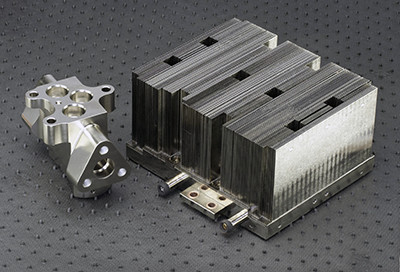

The trademark property of Anoplate's ENhanced Nickel coatings is their uniform thickness of deposit. Whereas conventional electroplating of complex shapes requires conforming anodes - which are sometimes difficult and costly to construct - no special fixtures are required when plating with ENhanced Nickel.

Sharp edges (for example, the tops of threads) which build up during electroplating are covered by Anoplate's ENhanced Nickel with the same uniform thickness as recessed areas (for example, the roots of threads).

The process is effective on steel, stainless steel, copper, aluminum, zinc die castings, powdered metal, and non-conductive materials.

ENhanced Nickel Advantages

ENhanced Nickel Advantages

- Uniform coverage - both internally and externally.

- Holds close tolerances by preventing uneven buildup.

- Even coating of threads, grooves, sharp corners, blind holes, and other complex shapes.

- Variable phosphorus content permits formulations geared to specific engineering properties.

| Formulation | Phos. Weight % | ASTM Type | Deposit Characteristics | Hardness RC As-Deposited |

|---|---|---|---|---|

| ENhanced LP9 | 4-6 | III | Consistent appearance over entire bath life;moderate corrosion resistance. | 56-61 |

| ENhanced MP6 | 6-9 | IV | Bright deposit; good corrosion resistance; HRC 68-70 if baked. | 45-50 |

| ENhanced HP101 | 10-12 | V | Excellent corrosion resistance;best ductility; non-magnetic. | 45-48 |

| ENhanced PTFE | 10-12 | n/a | Low friction, self lubricating;contains 20-25% PTFE by volume. | n/a |

For questions about this process or if you would you like to discuss an application for ENhanced Nickel? Contact Us Today.