Lead-free, RoHS-Compliant Replacement for Tin-Lead Electroplating

Technical Data Sheet - AnoTin Bi

Environmentally responsible OEM’s coupled with a myriad of European Legislation known as RoHS, WEEE and ELV are mandating products free from hazardous substances including lead. Electronic applications have employed tin-lead on components for which alternative finishes must now be specified, however, due to the real propensity for pure tin electrodeposits to form whiskers or tin pest, many OEM’s are reluctant to specify pure tin plating.

AnoTin Bi has been qualified by its demonstrated capability to pass 1,000 hours of continuous exposure to -40°C without exhibiting tin pest as would be evidenced by flaking or peeling. AnoTin Bi represents proven technology used to deposit a process controlled alloy of tin bismuth which can be directly substituted for any tin-lead plating callout

Product Description

- Matte, high tin alloy deposit that contains controlled addition of bismuth

- Can be deposited on nearly any substrate with options for copper, electroless nickel, or electroplated nickel underplate

- Meets ASTM B-545, MIL-T-10727and various corporate specs including IBM, GE, Rockwell Collins, Raytheon

- 100% Lead free deposit in compliance with RoHS, ELV and WEEE regulations

Physical Properties

|

Composition:

|

Tin: |

97.0 – 99.5% |

| Bismuth: | 0.5 – 3.0% | |

| Carbon: | 0.05% Max | |

| Impurities: | <0.5% | |

| Appearance: | White, matte, unbrightened tin | |

| Solderability: | Readily solderable with Type R flux | |

| Melting Point: |

450° F / 232° C |

|

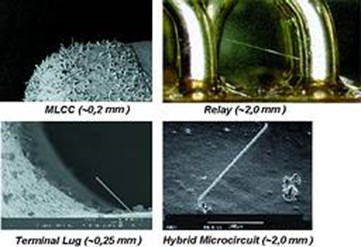

Unalloyed tin electroplating has a long history of whisker formation and growth resulting in reliability problems for various types of electronic equipment

.

Summary

Anoplate’s AnoTin Bi offers the advantages of tinlead plating to electronic manufacturers while minimizing the risk of tin whiskers or tin-pest.

With an internationally accredited ISO 14001 Environmental Management System, Anoplate is committed to routinely reducing its environmental impact – Anoplate’s AnoTin Bi is another product of that commitment

Tin pest shown here is an allotropic, naturally occurring transformation from white β-tin to gray α-tin that results in the tin coating crumbling off the plated component. Prevalent in cold weather applications, the likelihood of transformation is greatly reduced by incorporating bismuth in the deposit.

For questions about this process or if you would you like to discuss an application for AnoTin BI? Contact Us Today.

CONTACT US ONLINE

(315) 471-6143