RoHS-Compliant, Mid-Phosphorus Electroless Nickel

Technical Data Sheet - Enhanced MP6

A noplate’s ENhanced MP6 offers all the advantages of a mid-phosphorus grade electroless nickel to manufacturers without concern over compliance to stringent environmental regulations (e.g. RoHS, WEEE, ELV) that restrict or ban the presence of intentionally added lead or cadmium typically found in the majority of electroless nickel deposits. With an internationally accredited ISO 14001 Environmental Management System, Anoplate is committed to routinely reducing its environmental footprint – Anoplate’s ENhanced MP6 is the product of that commitment.

noplate’s ENhanced MP6 offers all the advantages of a mid-phosphorus grade electroless nickel to manufacturers without concern over compliance to stringent environmental regulations (e.g. RoHS, WEEE, ELV) that restrict or ban the presence of intentionally added lead or cadmium typically found in the majority of electroless nickel deposits. With an internationally accredited ISO 14001 Environmental Management System, Anoplate is committed to routinely reducing its environmental footprint – Anoplate’s ENhanced MP6 is the product of that commitment.

Benefits

- Corrosion resistant electroless nickel plating system employing the latest in chemical innovation, coupled with Anoplate’s proprietary plating equipment.

- Mid-phosphorus composition, typically 7-9% by weight, offering a good blend of corrosion and wear resistance

- Appealing metallic luster with consistent bright nickel appearance

- Ultra-smooth deposit with consistently low coefficient of friction

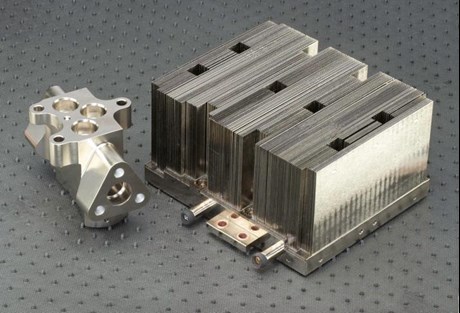

- Deposits evenly on all surfaces, unlike electroplating baths (see heat sink in photo)

- Can be thermally treated to increase hardness of the nickel phosphorus alloy to an equivalent hardness of 66 Rockwell C

ENhanced MP6 can be applied to a wide variety of materials, including:

- Steels

- Stainless Steels

- Inconel, Monel, Invar, Kovar

- Aluminum (picture shown)

- Brass & Copper

ENhanced MP6 meets and exceeds the following requirements:

- AMS 2404

- AMS-C-26074 (formerly MIL-C-26074)

- ASTM B 733 Type V

Film Thickness & Tolerances

ENhanced MP6 is typically specified for thicknesses in the range of 0.0002”-0.001”, but can easily be applied to thicknesses up to 0.003”. For extreme corrosion applications, it is recommended for deposit thickness greater than 0.001” per surface.

Typical Applications

ENhanced MP6 should be applied where tight tolerances, corrosion resistance, and durability are required. ENhanced MP6 is an excellent solution for the following applications:

- Turbine engine seals

- Locomotive brake components

- Medical diagnostic equipment

- Injection molds

- Hydraulic cylinders

Physical Properties

|

Composition:

|

Nickel: |

91-93% |

| Phosphorus: | 7 – 9% | |

| Cadmium: | ~0 ppm | |

| Lead: | <1,000 ppm | |

| Appearance: | Bright metallic luster | |

| Micro-structure: | Slightly crystalline | |

| Magnetic Coercivity: |

Slightly magnetic as-plated |

|

Deposit Hardness: |

53 HRC As-deposited |

|

|

67 HRC Heat-treated |

||

| Electrical Resistivity: |

70-100 µΩ/cm |

|

| Melting Range: | 880 – 1,100°C | |

Wear Resistance: |

16-20 TWI* As-Deposited | |

| 10-12 TWI Heat-Treated | ||

| Corrosion Resistance:* | >100 hours | |

*TWI = Taber Wear Index, mg/1,000 cycles using CS-10 wheels

**When tested per ASTM B117

For questions about this process or if you would you like to discuss an application for Enhanced MP6? Contact Us Today.

CONTACT US ONLINE

(315) 471-6143