Anoplate’s AnoTin Bi has been qualified by its demonstrated capability to pass 1,000 hours of continuous exposure to -40o C without exhibiting tin pest as would be evidenced by flaking or peeling. AnoTin Bi represents proven technology used to deposit a process controlled alloy of tin bismuth which can be directly substituted for any tin or tin-lead plating callout.

Tin pest is an allotropic, naturally occurring transformation from white β-tin to gray α-tin that results in the tin coating crumbling off the plated component. Prevalent in cold weather applications, the likelihood of transformation is greatly reduced by incorporating bismuth in the deposit. This provides a solid alternative for OEM’s are reluctant to specify puretin plating.

Tin pest is an allotropic, naturally occurring transformation from white β-tin to gray α-tin that results in the tin coating crumbling off the plated component. Prevalent in cold weather applications, the likelihood of transformation is greatly reduced by incorporating bismuth in the deposit. This provides a solid alternative for OEM’s are reluctant to specify puretin plating.

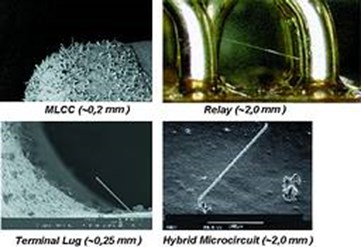

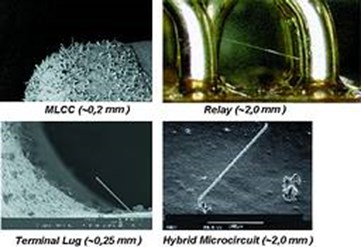

Unalloyed tin Electroplating has a long history of whisker formation and growth resulting reliability problems for various types of

electronic equipment.

PHYSICAL PROPERTIES

| Composition |

Tin: 97.0 – 99.5% Bismuth: 0.5 – 3.0% Carbon 0.05% Max Impurities <0.5% |

| Appearance: | White, matte, unbrightened tin |

| Solderability: | Readily solderable with Type R flux |

| Melting Point: | 450o F / 232o C |

PRODUCT DESCRIPTION

❖ Matte, high tin alloy deposit that contains controlled addition of bismuth

❖ Can be deposited on nearly any substrate with options for copper, electroless nickel, or electroplated nickel underplate

❖ Meets ASTM B-545, MIL-T-10727 and various corporate specs including IBM, GE, Rockwell Collins, and Raytheon

❖ 100% Lead-free deposit in compliance with ROHS, ELV and WEEE regulations

--

Anotin-Bi coating, Anoplate news, Surface finishing technology, Metal surface treatment, Corrosion-resistant coatings, Aerospace coatings, Industrial coatings, Anoplate services, Metal finishing solutions, Advanced surface treatments, Anoplate updates, Anoplate innovations, Chemical surface treatments, Metal protection solutions, Anoplate industry insights, Anoplate