News & Events

-

Durable, Deep Black Coating for Critical Optical Components

AnoBlack Cr (MIL-C-14538) is Anoplate’s proprietary black chrome deposit. Learn more about our finishes here.…

-

Anoplate’s Zynik II is a proprietary electrodeposited zinc-nickel alloy containing typically 12-16% nickel by weight which provides excellent corrosion resistance and durability over conventional zinc and other zinc alloys platings. It also provides a more environment-friendly replacement for cadmium-plating. Zynik II uses a proven alkaline, non-cyanide plating chemistry for even thickness distribution and excellent alloy distribution, ensuring that the corrosion benefits of the alloy reach in …

-

Black Oxide: Good Looking Rust!

Black oxide, also known as " gun bluing," is one of the lowest tech coatings Anoplate applies, yet it is also one of the most popular. In fact, Anoplate has invested in a new black oxide line to help meet the demand.…

-

Electroless Nickel Line Expansion

Anoplate continues to make significant capital upgrades to its facility including an expansion of its electroless nickel (EN) capabilities. In addition to its hand EN line, Anoplate has a linear, manually operated hoist line utilizing the latest chemical technology to produce high phosphorus grade EN deposits on steel and copper substrates.…

-

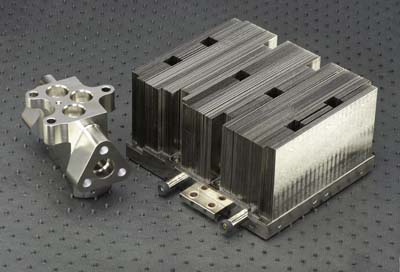

Anodizing for High Tolerance Parts

Using a modified sulfuric acid electrolyte and enhanced power control, Anoplate has developed, tested, analyzed and is now launching a revolutionary new anodizing technology called AnoTole.…