News & Events

-

Anoplate’s Zynik II Exceeds AMS 2461 Requirements

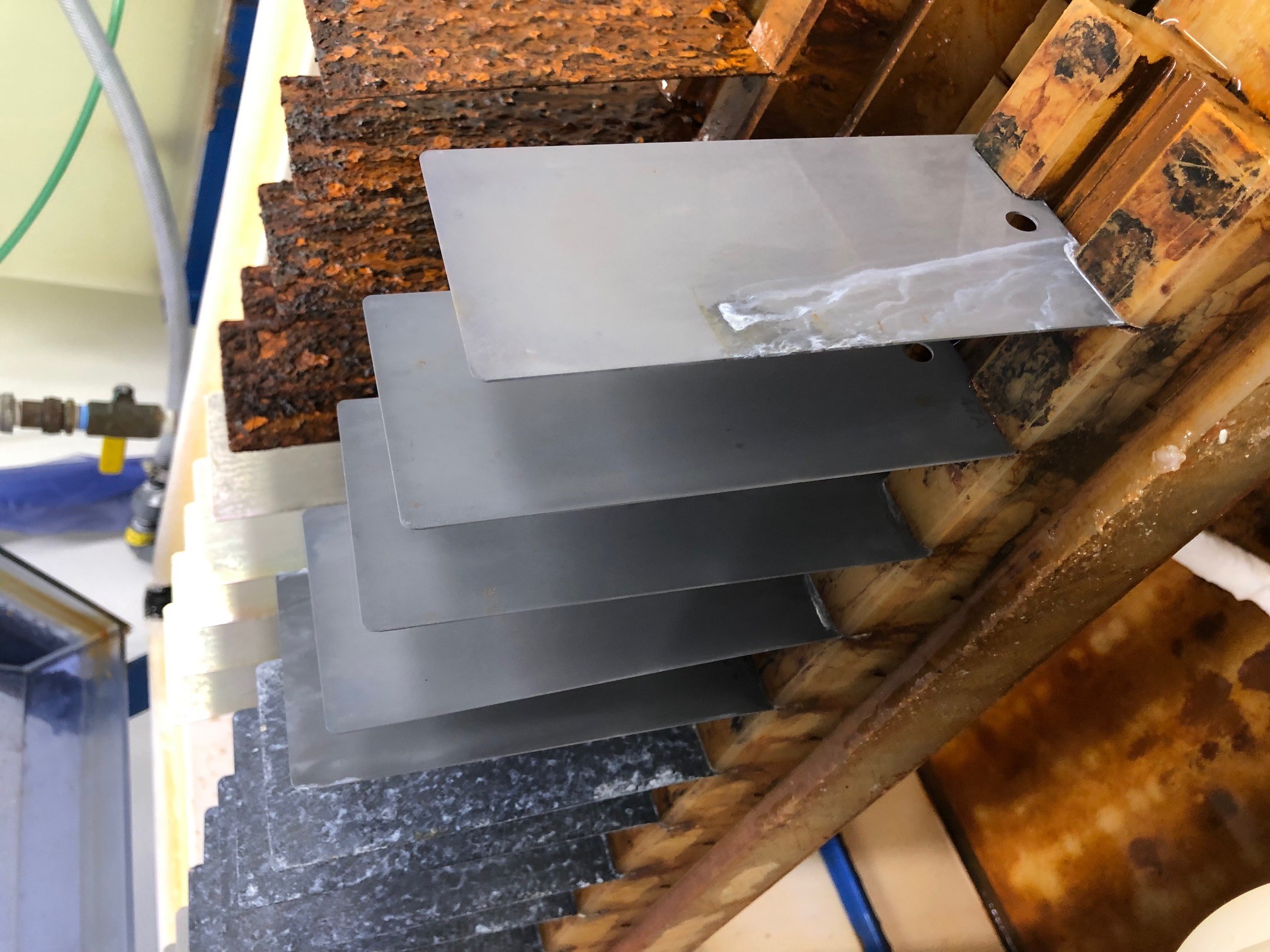

In November 2020 SAE’s AMS Finishes Processes and Fluids Committee B in conjunction with the International Aerospace Environmental Group’s (IAEG) Replacement Technologies Work Group released AMS 2461 covering gamma-phase zinc-nickel deposits (12-16 weight % nickel) from alkaline baths. The initial AMS specification governing zinc-nickel plating, AMS 2417, allowed nickel content of the deposit from 6 to 20 weight percent nickel and permitted the use of both acid and alkaline formulations. It ha…

-

Is Electroless Nickel ‘A’ Finish?

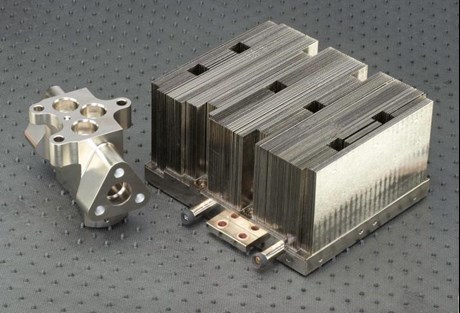

Simply put, not when it comes to Anoplate! Anoplate’s VP of Technology, Milt Stevenson Jr., presented a paper at the American Electroplaters’ Society SURFIN 1991 entitled “Electroless Nickel: No Longer Just ‘A’ Coating”. It wasn’t then and it isn’t today! [ A copy of that paper can be found by visiting Anoplate’s website] Non-magnetic, high phosphorus electroless nickel is required for disk drive components. Today Anoplate’s ENhanced suite of electroless nickel (EN) offers 7 variants repr…

-

Anoplate Still Has A Knack for Black

With some of its early roots in the optics world of nearby Rochester, Anoplate has been blackening parts for better than 60 years. Cutting its teeth on such optic giants as Kodak, Bausch & Lomb, and Haloid what became Xerox), Anoplate was continually challenged to produce consistent, black finishes ranging from matte black anodize on carousel slide projector lenses to black zinc on die cast yokes used to affix carrying straps to cameras. Today Anoplate is applying its AnoBlack Cr on aero…

-

Anodizing is a method for changing the surface chemistry of metals and other substrates. However, it generally refers to anodizing aluminum. It protects against corrosion, enhances aesthetic qualities, resists scratching, and is one of the most durable surface finishes available. The transportation industry uses about 30% of all the aluminum manufactured in the United States, making it the number one market for aluminum. Automakers use aluminum for applications that include wheels, frames, cy…

-

Anodized aluminum is for the most part a robust, quality finish that is readily obtained through any number of chemical processing houses, however, a persistent issue that arises is fading of colored anodize. The fact is that there are a number of causes for this, not always related to the processing houses cutting corners, so we thought we‘d review some of them.…