The AnoBlack 606 process is a unique amalgamation of chemical pretreatment with post-electrochemical processing that creates an ultra-matte black appearance on wrought aluminum alloys. The micro-etched surface lowering the glossiness as well as blending in mild scratches and minimizes die line visibility for added durability making this material perfect not only to protect but also to showcase your pieces!

The AnoBlack 606 process is a low-cost, and more uniform, alternative to mechanical blasting. Unlike mechanical blasting, the 606 proprietary etch provides a uniform removal rate, typically removing less than .0001” per surface! The finish works best with 6000 series aluminum alloy and is not intended for use on aluminum castings.

Applications

- Firearms

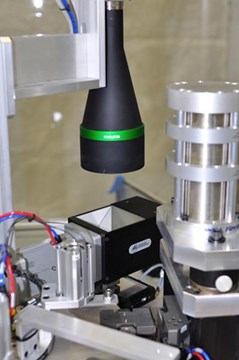

- Telescopes, cameras, and optical components

- Medical instrumentation or surgical components

- Vision control robotic systems

- Surface mount electronic assembly automation components

Advantages

- Uniform matte, non-reflective appearance

- Eliminates the Need for Sand Blasting or Glass Beading

- While typically black, can be done matte clear or dyed other colors

- Low Reflectivity and Various Levels of “Frosted” Appearance Attainable

The AnoBlack finish was developed through years of research and development to offer a unique solution for surface engineering challenges.The AnoBlack family of coatings include:

--

AnoBlack 606 process, Matte black aluminum alloys, Chemical pretreatment, Post-electrochemical processing, Surface engineering solutions, Uniform matte appearance, AnoBlack finish applications, AnoBlack family coatings, Anoplate